Product Description

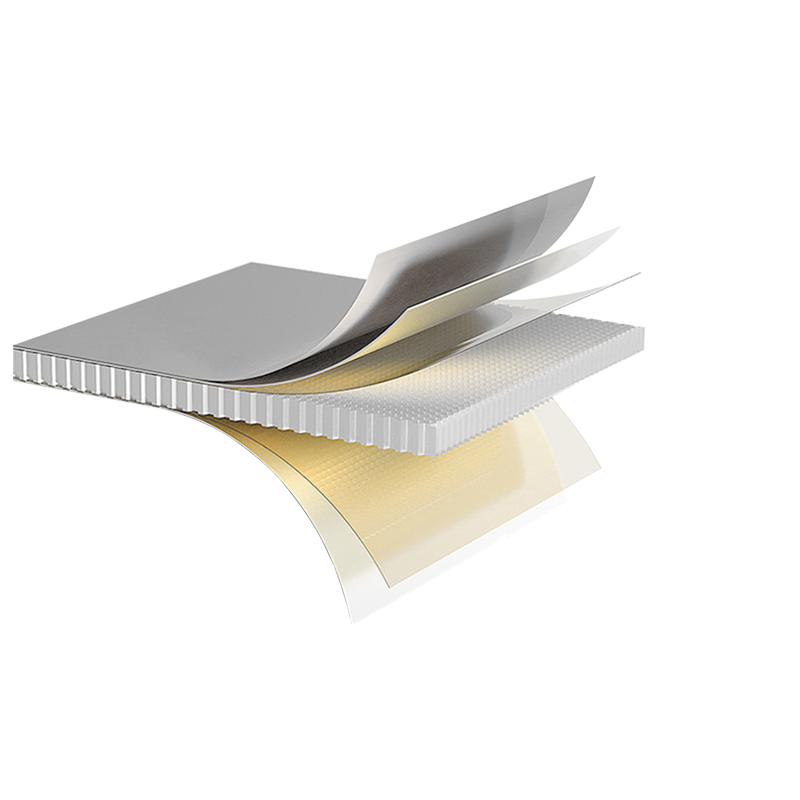

The core of the aluminum honeycomb panel is a hexagonal aluminum honeycomb core layer with a density of only 4.5kg/㎡, which is 20% of the weight of the same specification wood board, 16.7% of glass, and 14.3% of solid aluminum plate. Its honeycomb cavity structure forms a natural sound and heat barrier, achieving 30dB airborne sound insulation and 0.02 (㎡·K/W) thermal resistance. The matrix does not contain combustible substances and meets the B1 fire protection standard. It has both waterproof and moisture-proof properties and zero harmful gas release. The strength and stiffness performance per unit mass are excellent (the structural stiffness is 70% higher than that of the ribbed structure), which completely solves the deformation and collapse problem of large-size decorative panels and supports free cutting and folding processing.

Parameter

|

Product name |

The latest aluminum-steel composite panels |

|

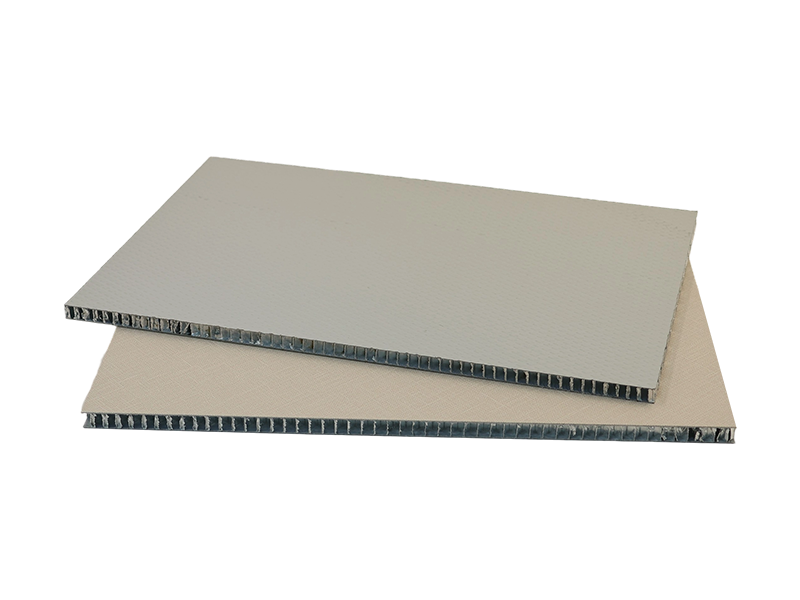

Color |

Customized based on customer needs |

|

Size |

1200mm*2600mm or 1200mm*2800mm |

|

Thickness |

8mm |

|

Honeycomb core |

A4 |

|

Surface steel sheet |

0.2mm |

|

Bottom steel sheet |

0.13mm |

|

Surface Treatment |

Melamine paper |

|

Certificate |

ISO9001, ISO14001, CE, SGS test, CP65 test |

|

Thickness deviation |

±0.15mm |

|

Flatness deviation |

±0.2mm |

|

Use |

Indoor decoration; Commercial places; Industrial places; Medical places; Public places, etc. |

|

Function |

Waterproof; moisture-proof; fireproof; antibacterial; mildew-proof; corrosion-resistant; light weight; strong impact resistance; large bearing capacity |

|

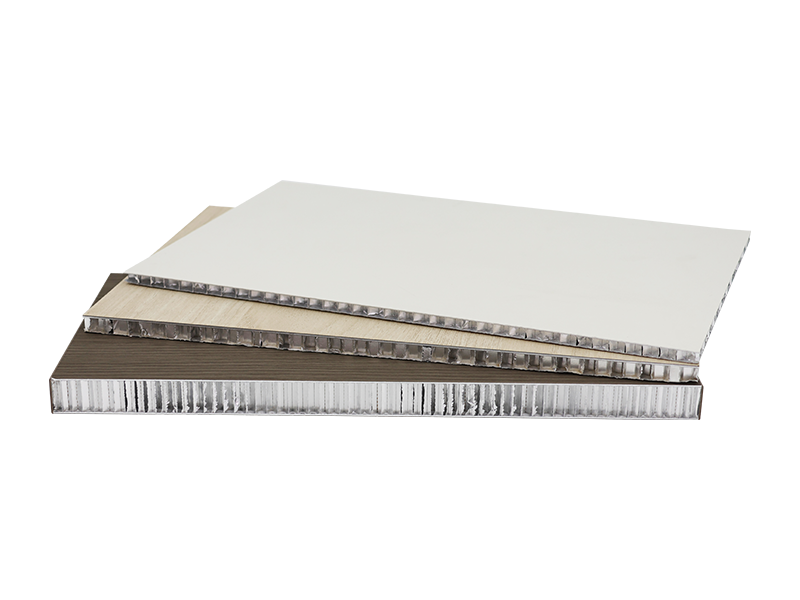

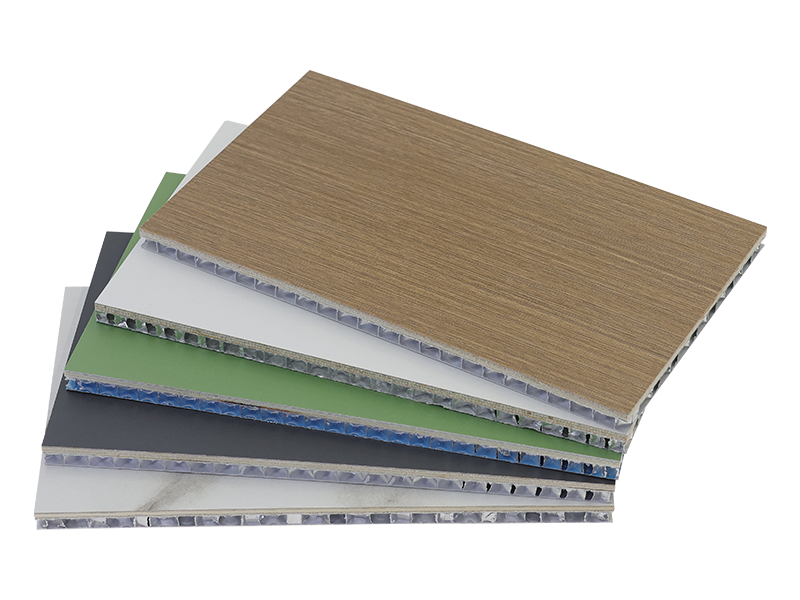

Film for option |

Hundreds of surface films available |

Application Description:

The latest aluminum-steel composite panels have become the preferred material for the construction of interior walls and ceilings in multiple fields due to their excellent structural performance and decorative adaptability:

(1) High-end interior decoration projects: As the core material of the wall system, it combines aesthetic expression with long-term durability;

(2) Aircraft manufacturing: Applied to the inner wall and compartment structure of the cabin to meet the lightweight strength requirements in extreme environments;

(3) Commercial space solutions: Create high-load-bearing interior partitions and product display platforms to achieve the unity of function and aesthetics;

(4) Logistics and transportation equipment manufacturing: Provide anti-corrosion protective layers for commercial transport vehicles and container bodies to extend the service life of equipment;

(5) Public transportation vehicle projects: Cover the interiors of buses and rail transit vehicles to improve safety and modern texture.

Product Structure

|

|

Shipping Packaging:

The panel will be covered with protective film, pearl cotton, PE film, corner guard, packaging, etc., and reinforced with strapping and packed with wooden pallets.

Product advantages:

Lightweight construction

The composite structure of stainless steel plate and aluminum honeycomb core significantly reduces the material density and achieves excellent lightweight properties.

Ultra-high structural strength

The aluminum steel matrix and honeycomb core are synergistically enhanced, and the mechanical properties far exceed those of conventional plates.

Long-term corrosion protection

The natural corrosion resistance of aluminum steel material combined with the galvanizing process forms a dual anti-oxidation and chemical erosion barrier.

Surface durability system

The galvanized layer strengthens the hardness of the substrate, and the triamine paper finish improves the wear resistance level, greatly extending the product life.

Moisture protection mechanism

The triamine paper surface layer is dense and waterproof, and the honeycomb core is moisture-resistant and does not absorb moisture, effectively avoiding the risk of expansion and deformation.

Active fire protection

The non-combustible properties of the aluminum steel matrix combined with the triamine paper flame-retardant surface layer form efficient fire retardant performance.

Ecological safety guarantee

German PUR hot melt and polymer cast film are compositely cured at 200℃ by hot pressing to achieve zero formaldehyde release; the material is recyclable, environmentally friendly and has secondary benefits.

Customized aesthetic solutions

We offer a variety of melamine paper finishes to choose from, supporting batch customization to meet diverse design needs.

FAQ

We operate as a specialized decoration and furniture panel production facility with integrated manufacturing capabilities.

Yes, samples are free, only freight is charged.

Comprehensive OEM/ODM services are available to meet specific technical requirements.

Standard items: 7 business days

Custom projects: 15-30 business days

LULENGT's 17-year industry expertise includes:

✓ Patented technologies

✓ ISO 9001 & ISO 14001 certified operations

✓ Third-party verified compliance (SGS/CE/CP65)

certification

![Patent certificate [A water-washing cabinet that is convenient for cleaning dead corners] Patent certificate [A water-washing cabinet that is convenient for cleaning dead corners]](/npublic/img/s.png)

![Patent certificate [A wardrobe with heating and dehumidification functions] Patent certificate [A wardrobe with heating and dehumidification functions]](/npublic/img/s.png)

![Patent certificate [A wall-mounted storage cabinet that is easy to install] Patent certificate [A wall-mounted storage cabinet that is easy to install]](/npublic/img/s.png)

![Patent certificate [A classified storage cabinet with partition distance adjustment function] Patent certificate [A classified storage cabinet with partition distance adjustment function]](/npublic/img/s.png)

![Patent certificate [A cabinet with sterilization function] Patent certificate [A cabinet with sterilization function]](/npublic/img/s.png)

The Latest Aluminum-Steel Composite Panels

Classification

Contact Us

OEM&ODM Customization

We are a manufacturer with 17 years of experience in R&D, production and sales of interior panels. We can provide you with professional OEM & ODM services.

Send your requirements

Send samples or customers to visit our factory

Confirm the panel material, size, quantity, price, PVC color, product delivery time, etc.

The customer should pay 30%payment first, and we arrange factory production

Follow up on production progress and synchronize it with customers

Inspect the goods, make the final payment, and arrange for shipment and transportation

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Distributor Following

Welcome same-minded global partners to expand your local market together!

You need to meet the following conditions:

1. Some experience in the Building Materials Industry

2. There are certain sales channels available

3.Love and decide to explore the local market together

Whatsapp: +86 19926019345

Welcome to leave a message!